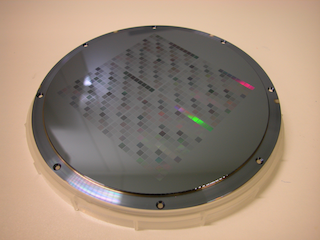

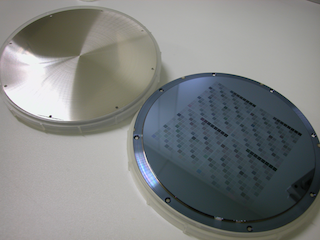

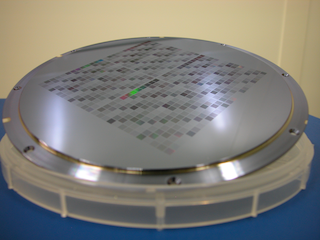

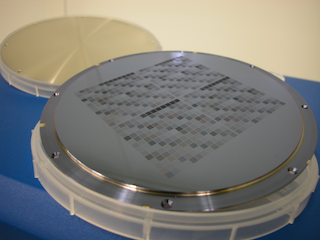

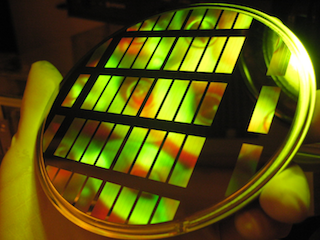

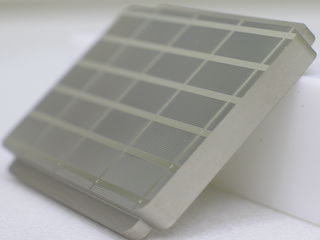

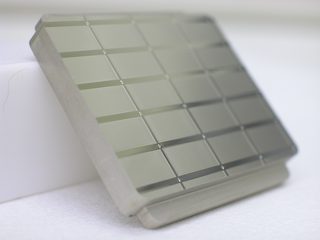

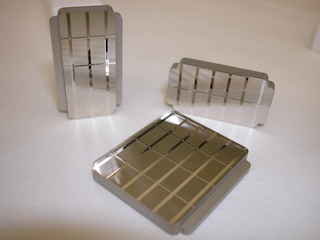

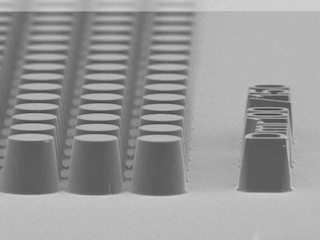

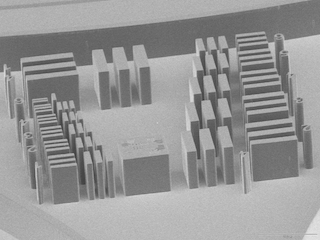

Hot-embossing stamps

Characteristics:

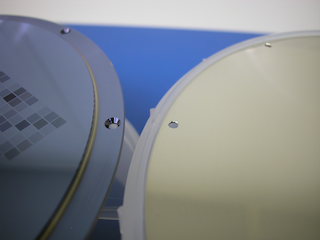

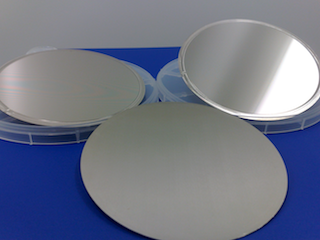

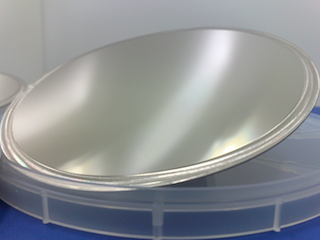

Master with a thickness range 0.5 - 3mm are being used on hot-embossing machines. Preferably called “stamp " The stamp is being screwed tightly to either heated base plate. An excellent physical contact between hotplate and stamp is vital to ensure proper thermal coupling.

Material: PDMS (silicone) soft stamp, silicon wafer, EF-Nickel or Steel-stamps

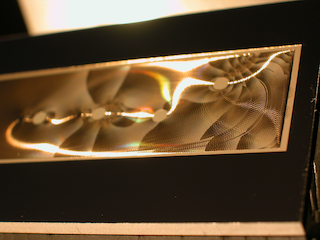

Applications: nano- and microoptics, microfluidics.

1. Convert customer data into Maskdesign

2. Fabrication of maskset

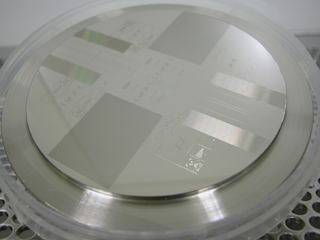

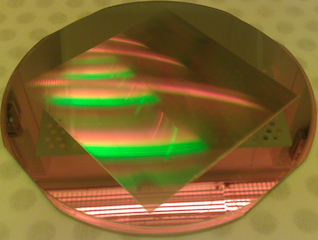

3. Lithography on substrates =» resist-master

4. Prepare the master for Ni-electroforming =» Nickel-master (pattern inverted / mirrored)

5. Removal of wafer and resist

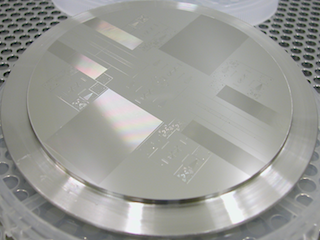

6. Mechanical post-processing the geometry of the stamp for mounting on the hot-embossing machine.

1. Prepare the customer-substrate for Ni-electroforming =» Nickel-master

2. Removal of wafer and resist

3. Mechanical post-processing of the stamp geometry for mounting on the hot-embossing machine.

Specifications:

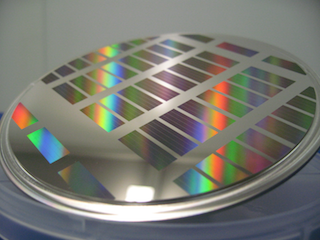

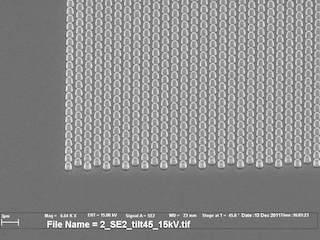

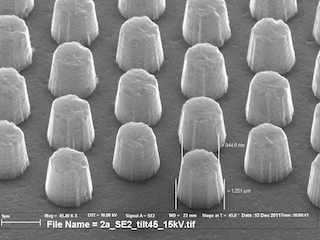

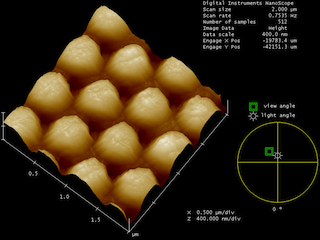

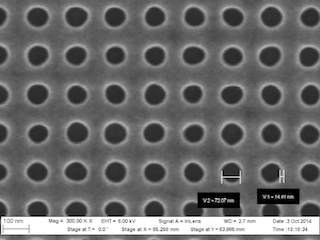

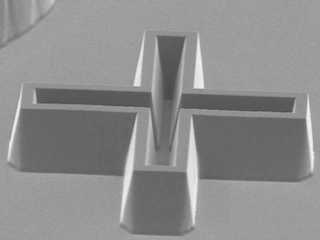

- Pattern depth range = 70nm - 500μm

- Pattern height uniformity = 3 – 5%

- EXCLUSIVE: Adjustable drafted sidewalls up to 15° (easy demolding)

- Manufacturing according to adapted LiGA-process

- Multilevel pattern available (micro+nano)

- Alignment-precision: level-to-level ≤ 3μm

- Alignment-precision: micropattern to machined features ≤ 20μm

- Stamp thickness = 0.5 - 3mm

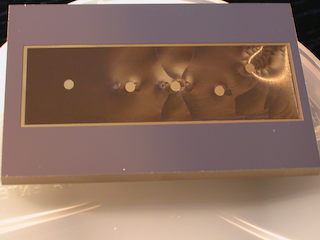

- Maximal stamp dimensions = 300 x 300mm

- Maximal patterned area = 200 x 200mm

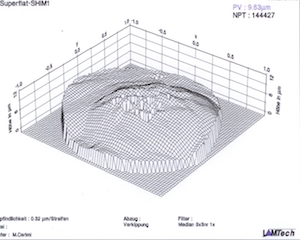

- Parallelism Frontside-to-backside ≤ 20μm (Backside: surface grinded)

- Robust handling

- Integration of mechanical mounting features

- Ready-to-use stamps according to customer drawing

- Contour wire-electrodischarge machined (tolerance = ± 10µm)

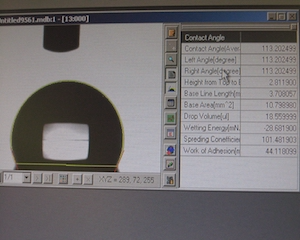

- Available antisticking-coating (fluoro-based)

- Available wear-protection coating (TiN)

- Compatibility to most patterning methods: - e-beam resists (PMMA, HSQ)

- XIL-resists

- UV-lithography: AZ positive resists, Microchem SU-8

- Hot-embossed polymers, Thermal imprinting,...